TCC

TCC - Liquid Mixer Mobile

Construction Features

- Tank chamber in AISI 316L with mirror polished

- Thermoregulation jacket

- Insulated jacket with rock wool and sheet inox AISI 304 external welded to the shell

- Useful capacity: 1 liter to 500 liters

- Bottom valve zero dead leg

- Electrical and control cabinet on board

- Also available in the Ex version for Atex classified environments

TCC

TAIM designs and builds a series of wheeled mixers, practical and ergonomic for preparing medium viscosity pharmaceutical liquids.

Il TCC is ideal for those looking for an efficient and flexible mobile tank at the same time is also available in the version with heating with electric heaters with water for temperature < 95 °C or with diathermic oil for higher temperatures > 95 °C

The TCC is made with a top cover with a double opening system. The main cover is flat and has a solid rear hinge; inside this hinge, protected by a suitable carter, a spring device is positioned to cancel the weight of the cover and facilitate its opening, in full compliance with all the safety requirements concerning crushing.

Furthermore, a safety microswitch is placed inside the hinge which inhibits the operation of the agitator if the lid is open.

On the lower face of the lid there is a special dou- ble lip seal and dovetail to ensure the hermetic closure of the inside of the dissolver.

On the lid there are the closing knobs of the same, and on the hinge there is a lock knob of the open cover, which automatically intervenes when the lid is completely opened, preventing acciden- tal closure.

Inside the cover there is a half-moon (second cover) for inspecting the inside of the chamber during processing and possibly loading other products. In fact, under the flap, there is a safety grid, welded, which also prevents the shaft from coming into contact with the rotating shaft when it is open.

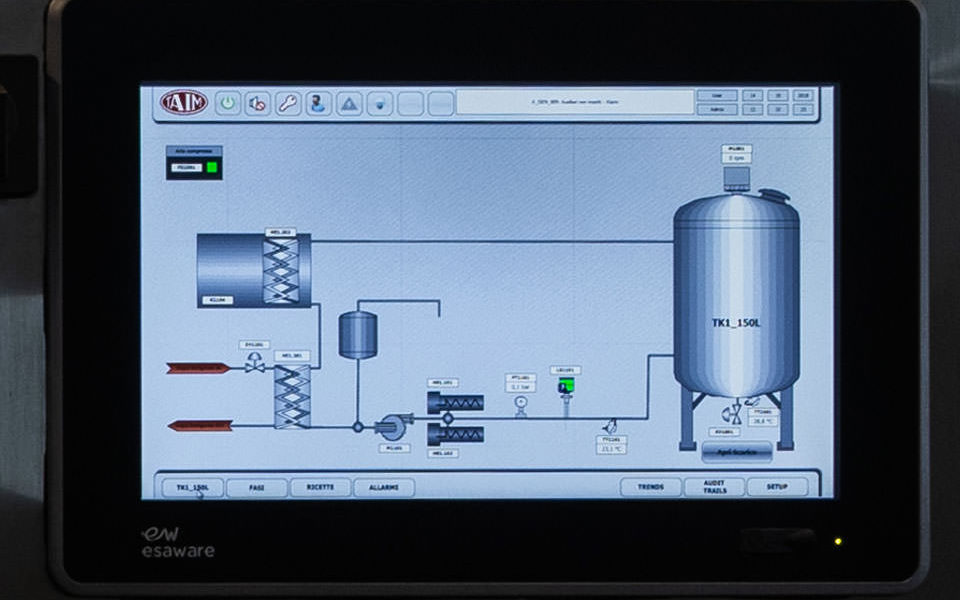

Control Panel

The following commands are accessible from the control panel:

- Start / Stop Mixer speed variator with current speed display in RPM

- Digital set-point heating temperature display of product temperature

- Dispaly of jacket temperature

- Spies and alarms

- Emergency button

Get Started

if you want more informations for our dynamic process, production flow and thecnologies, please contact us